dd43 - Page 4

Enhanced data delivery options for underground utilities

Recent studies and reports have highlighted the need for increased efficiency and productivity in the construction industry. Forward-thinking firms such as Queensland-based Bennett + Bennett have been considering ways to improve design and engineering processes by embracing digital technologies.

The 2019 update to the Australian Standard AS5488 has assisted by prescribing the consistent approach needed for the classification of information gathered in the field. Part 2 of the Standard focusses on Subsurface Utility Engineering (SUE) and outlines naming conventions, additional metadata requirements, the level of model creation required, the roles and responsibilities of the various stakeholders, a framework for utility clash coordination and resolution, and the level of documentation needed for asset handover.

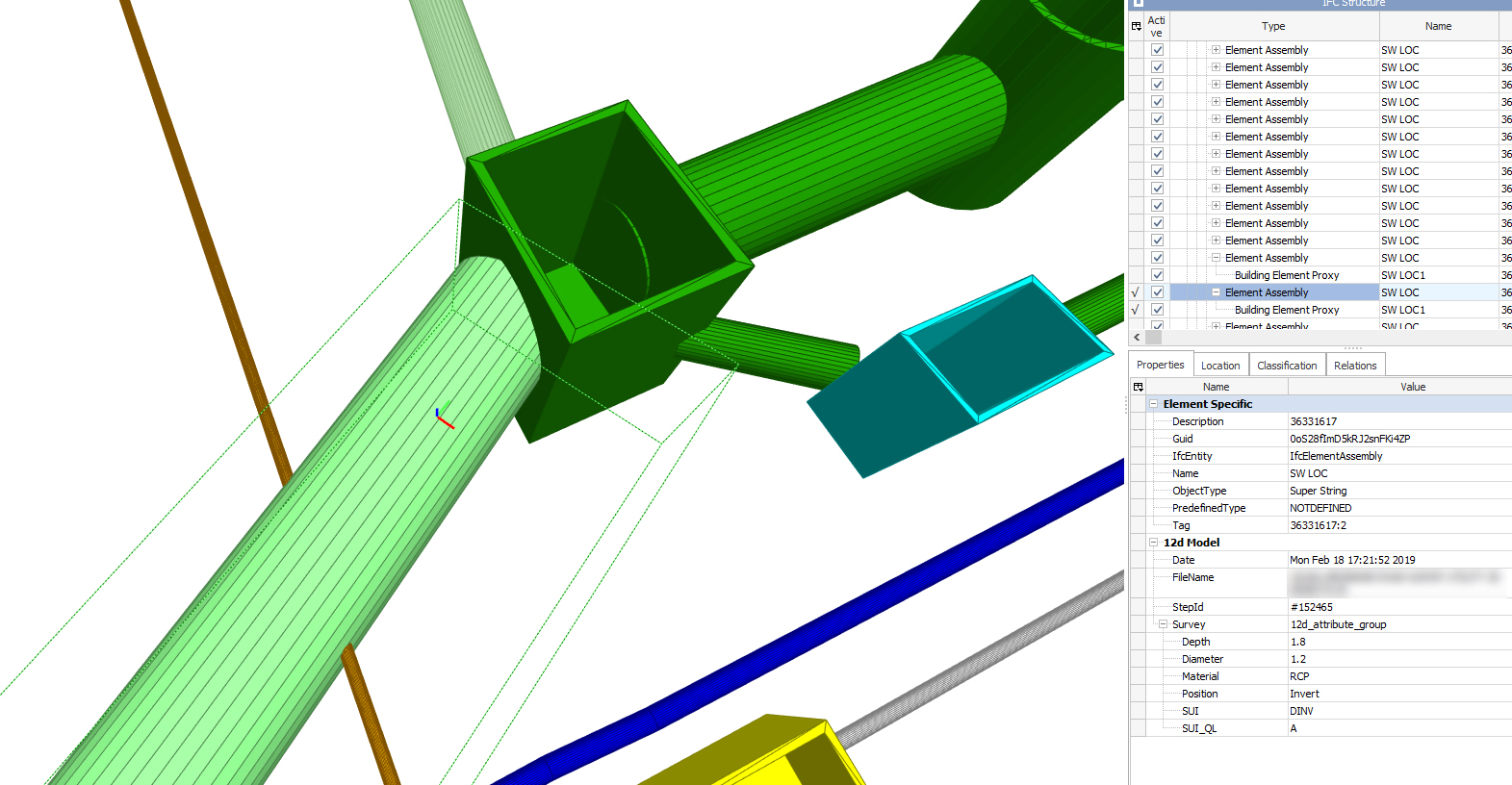

As software, collaborative workflows, and common data environment platforms improve, there are increasing benefits to having enhanced datasets, allowing for faster, more accurate, and more efficient planning and construction. Utilising this data with proposed project data better communicates design intent through enhanced visualisation, analysis, animation, simulations, and plans. As the objects in a 3D model are spatially related, they can be viewed from multiple perspectives, allowing the designer to identify design and constructability concerns more easily before the design reaches the field.

Accurate enhanced 3D data modelling sometimes takes more time to complete than a traditional 2D design, but this trade-off in time is easily surpassed by the long-term advantages...extra planning at the start of a project means saving a lot of time in the long run.

12d Model software in particular has been invaluable to Bennett + Bennett in these processes. The capacity to push data right through from start to finish using BIM with Attributes to harness metadata has been especially important.

The added benefits of having a 3D Utility Model include the capacity to perform Clash Detection Analysis against proposed design elements, a greater understanding of, and ability to mitigate, risk, and the ability of Construction Teams to run tolerance checks to find areas requiring further pot (test) holes.

Bennett + Bennett has been able to create and upload ‘uncertainty buffer zones’ enclosing the true location of a utility - an extra safety measure to avoid utility strikes during excavation. Updated models can be supplied to the Facility manager as an as-constructed model.

12d Model’s seamless integration with other packages, and the use of 12d Model Visualisation, have been integral to making these Sub-Surface Utilities projects run smoothly. For more information, see Bennett + Bennett’s blog series on this topic: Part 1, Part 2, and Part 3.